What Can Be Made Of Color Coated Steel

- 5 years ago

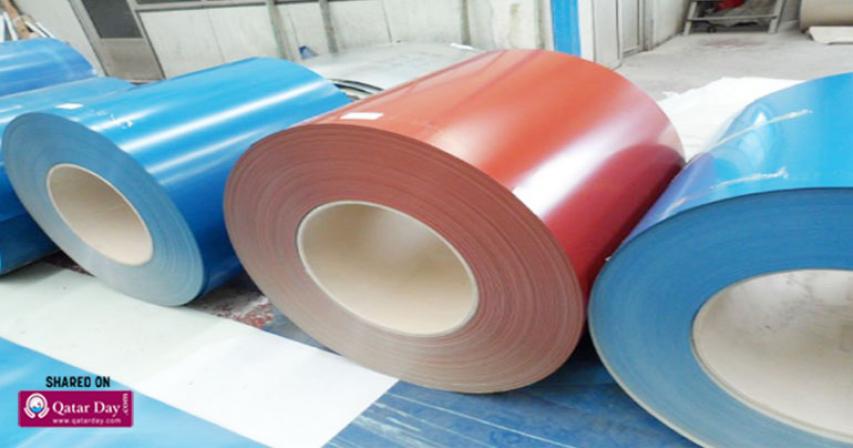

Color coated steel is widely used nowadays. There are many protective and decorative coatings. Each coating is distinguished by its composition, resistance to ultraviolet rays (the ability not to fade in the sun and retain color), resistance to temperature extremes and mechanical damage.

In order to make longer the period of operation of polymer steel products, they are coated with a special cladding during manufacture. The main purpose of this coating is to provide protection against corrosive processes. But in the same way, such products have a beautiful view.

Galvanized steel with polymer coating is widely used in building industry. Facade and roofing materials are produced from steel with polymer coating: metal siding, with various configurations, metal tile, corrugated flooring and additional elements for them.

Galvanized sheet with a polymer coating is widely used for the manufacture of facade and roofing materials.

The most popular polymer steel coatings are:

● Polyester,

● Polyester matt

● Aluzinc,

● PVC,

● Pural.

To obtain a high-quality material, steel sheet is coated primarily with zinc. The optimum coating thickness is 275 grams per square meter. If this coating is thinner, for example, 180 grams per square meter, then such a steel sheet will last 5-7 years less. Next, anti-corrosion phosphate coating is applied. The next layer is the primer. And only after that the polymer coating is applied. If the steel is unilateral coated, polymer coating is applied only on the outer side of the sheet, and a protective varnish - on the inner. If the coating is two-sided, then polymer coating is applied on both sides of the sheet.

METAL COATED STEEL

Products made of steel with a metallic coating, intended for use in a variety of corrosive environments, are designed to extend the life of the finished product, ensuring reliable protection of steel elements from corrosion. In addition, a properly selected metal coating simplifies the processing of such products, increasing their suitability for forming, welding and painting.

High-strength low-alloyed steel with a metal coating is intended for the manufacture of structures that are subject to increased requirements in terms of resistance to electrochemical corrosion and suitability for molding, combined with high strength.

An excellent combination of the suitability of steel for molding and its strength contributes, for example, to an increase in resistance to overloads, which allows the manufacture of relatively complex or lightweight structures without prejudice to their stability under load. Along with the usual zinc coating (Z), zinc-aluminum (ZA) or zinc-iron (ZF) coating is applied to increase corrosion protection of products. Providing protection against electrochemical corrosion, zinc-based coating extends the life of the main structures of such large structures as, for example, solar power plants, silos or bunkers.

Metal coatings of products are divided into zinc (Z), zinc-aluminum (ZA) and zinc-iron (ZF). The degree of protection against cathodic corrosion is directly proportional to the thickness of the metal coating, in other words, the thicker the coating, the better the steel is protected from corrosion. However, where good formability is required, thin coatings are recommended.

Comments